views

Innovation is the key and designing new products according to evolving market needs is the ultimate solution. So if you want to excel in your industry, you will require robust product design, development services and end-to-end product delivery.

Product design and development is entirely driven by human experience and creativity. With Technological advancements and updates, it has revolutionized the entire End-to-end product design and development solution.

These days, professionals use natural language processing (NLP) and knowledge graph-based techniques to gather customer feedback and implement that input to develop the final product. Compared to the traditional approaches and techniques, these modern techniques have higher accuracy and speed and are scaling up the user requirements in parallel with the market competition.

However, this industry is growing exponentially and requires special roles for user interface or UX designers. And today, UX researchers, interaction designers and copywriters also make a crucial contribution to the engineering and development of end products.

What Is End To End Product Development?

End to End Product Development is the process of identifying market opportunities, connecting user needs and requirements with business goals that help brands create consistently successful products.

It’s all about identifying the problem, developing a significant solution, and validating the solution with real users to evaluate the success of the product.

Our team helps you engineer product development from ideation and prototyping to end product delivery for scalable business growth.

As one of the best product development companies, we understand your target demographic and map out the product architecture to create a strong and unique position for your business in the market. Through user-centered design and efficient embedded product development, we help customers see the true benefit and true value of your product.

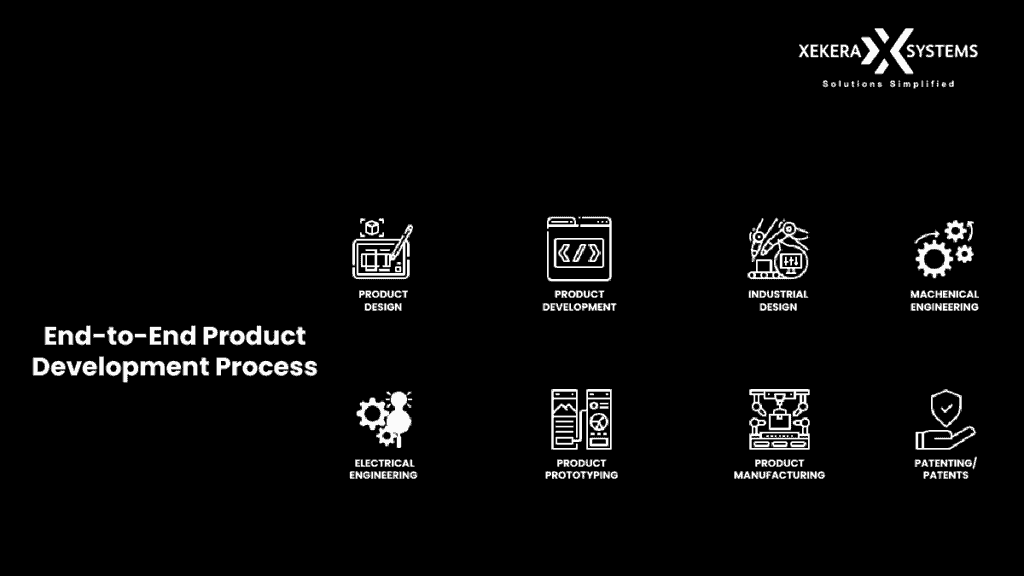

Let’s understand End-to-End Product Solutions and their development process in detail –

Product Design And Engineering Process

We follow a streamlined and advanced process of providing total hardware product engineering services that help businesses gain an edge over their competitors. Our process includes –

Generating Innovative Ideas

1. Brainstorming Sessions

Before diving into the design process, we discuss ideas and brainstorm to come up with problems and solutions. It is very important to ask and discuss the “Why” and strategize how our team will work on it.

With a clear vision in mind, we give our team of designers and product engineers a purpose for what they are trying to build.

Many times, professional designers jump right into design and development without having a clear idea of the client’s defined goals or requirements. This will eventually increase the no. revisions and can ultimately lead to disastrous results.

2. Defining The Product And Its Properties

After brainstorming, when all viable product ideas are selected, highlight and focus on the implementation part. Follow the MoSCoW categorization method when prioritizing product features. It starts –

- M = “Must have” some important and key features. Without these features, you cannot fulfill the purpose of the product.

- S = “Should have” some basic features that are not vital but add significant value to the product.

- C = “Could have” features that are not necessary for the basic function of the product. But it may leave less impact on the product if you missed it.

- W = “It will not have such features and functions that could have a negative impact on the product in the minds of customers.

When selecting a feature list, empathize with your users first and follow this approach, which is a basic, expected, and extended requirement of your product. Researchers often verify the suitability of this product in the market by conducting user research to better understand the customers.

3. Proof Of Concept

Conducting user research is extremely important to know your customers, understand the movements of your competitors, define current and potential trends, evaluate the potential lifespan of a product, and significantly leverage first-to-market advantage.

Some of the user research methods include-

User Interviews – Interviews are conducted in-person or remotely to uncover insights from direct conversions with users.

Online Surveys – Online surveys are conducted to collect a set of data from a large number of customers in a short period of time.

Contextual Inquiry – This allows you to empathize with your users by observing how they perform their routine tasks in their natural environment.

User analysis

After collecting user research data, we perform “affinity mapping” and synthesize our findings by categorizing them into groups. This allows you to draw insights from raw data to help you make informed decisions.

So based on these insights and results, you can justify the practicality of the concept before investing any resources. These research techniques will force you to think more realistically and thoroughly.

Product design

Sketching

The main goal behind sketching is to communicate the basic concept and reveal defects and flaws early on. Sketching a rough design does not require professionals. With artistic skills, your work will be done.

However, any large project with a significant budget requires advanced sketching technology to narrow down the direction of the main concept. Such technologies are –

CAD

Computer-Aided Design (CAD) is a technology for designing computer models from concepts and early sketches.

It replaces manual drawing with an automated process. This technique is typically used to build a prototype and advanced understanding of idea validation.

The output derived from a CAD design is many times used as input to a 3D printer to streamline the design process.

3D rendering

3D rendering refers to matching the similarity of an object and converting information from a 3D model into a 2D image. Thanks to this, you can see a good detail of color, shape, material and appearance.

However, if you add a background or animation to the image, you give life to the object. This will help you understand the typical look and feel of the product.

Technology is thus pushing its boundaries to support the future of product design. It goes beyond the incorporation of smart tools and customer insights and is essential in making low-cost manufacturing feasible along with high levels of automation.

Product Development

Hardware Development

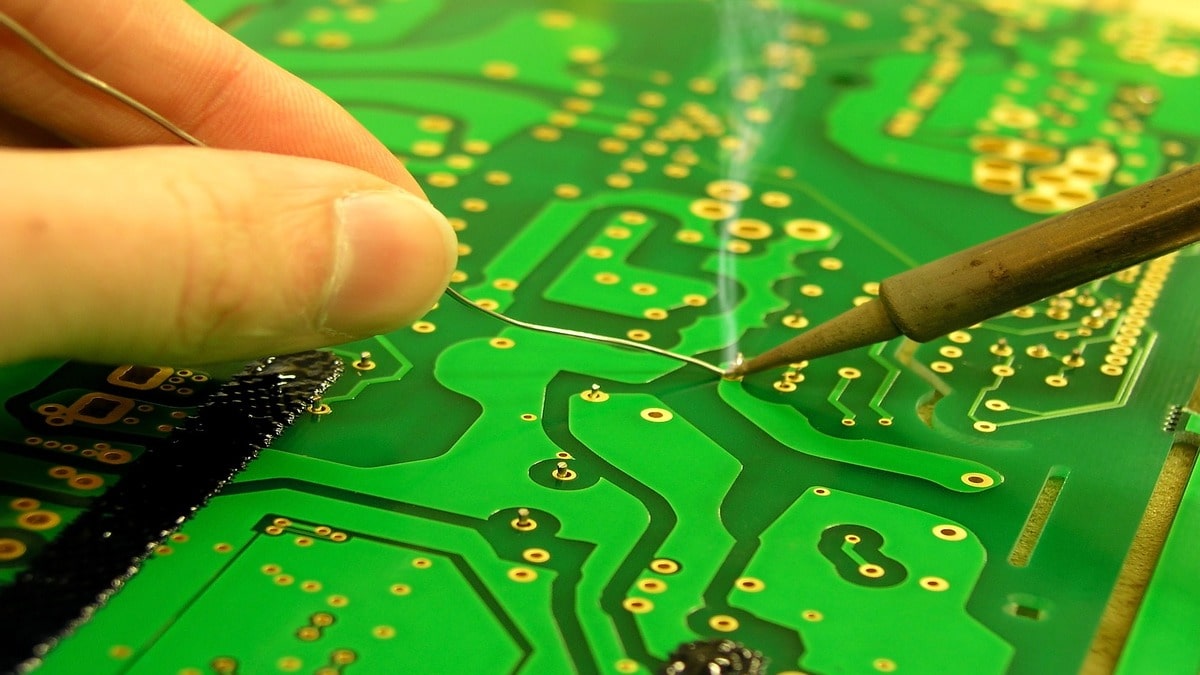

PCB design

After creating a 3D model, our certified engineers will design and build your PCB layout. We review every activity and ensure you come away with a cost-effective and pragmatically sized circuit board. In addition, our QA analyst is constantly working to scan for bugs and debug early stage flaws.

PCB creation and prototyping

Once the PCB layout is complete, our electronic engineers will start working on PCB creation and prototyping. Now, once the prototype is ready, you hold the actual product in your hands. Here we expect some revisions and adjustments to the product prototype before announcing it as the final version for production.

Costing process and BOM

Once the prototype is made, we gather all the materials needed to develop the electronic product. In addition, our team helps you connect with the best suppliers who deal with the most cost-effective rate without compromising on quality standards.

Creating a 3D model

Once the client approves the 2D mock-up, we start working on the 3D models and move on to the electronic product development. The best thing about 3D mockups is that they give a vivid look and feel of a product with a detailed specifications. ifour has the most advanced technology to create a successful 3D model for any product.

Technical drawings

Technical drawings are a blueprint that shows all the information and requirements needed to manufacture an item or product. You won’t need technical drawings for a conventional artistic sensibility. However, in a comprehensive sense, technical drawings become important for reviewing the design from a technical and manufacturing point of view.

Software Development

We select the operating system and develop all levels of device software: drivers, user interfaces, and production quality control testing programs. We have reduced the time and cost of designing and developing an embedded software device platform using ready-made open source solutions.

Industrial Design

Industrial design is the professional practice of designing objects, devices, products or services with a focus on physical appearance, manufacturability and functionality.

During the design process, industrial designers often focus on improving common life activities through well-executed design.

However, from a technical point of view, it consists of multiple two-dimensional functions and three-dimensional functions that serve as a model for solving problems for businesses and corporations through systems, services, innovative products and experiences.

Industrial design puts the person at the center and interacts with the products used in the daily routine. It gives you a more optimistic view of the future by reframing problems as opportunities to co-create a better quality of life.

Mechanical Engineering

Mechanical engineering is a process of conceptual and detailed design that includes stress and vibration analysis and more through advanced manufacturing equipment and high-speed mechanisms.

We work seamlessly with our clients to deliver the best design with a strong focus on manufacturing. In addition, we have a broad focus on high-speed mechanical dynamics analysis, electromagnetic interference shielding and value engineering.

Our experience in 3D printing, sheet metal, machining, and various surface finishing options allows our designers to help you find the most cost-effective options for your machine design needs.

Electrical Engineering

Electrical engineering services represent a comprehensive physical hardware platform development technique for high-end consumer electronics products. Our team works closely with our systems engineers to significantly deliver product architectures.

We can help you with circuit design and analysis, firmware development, radio frequency (RF) systems, remote sensing, Wi-Fi integration, Bluetooth, Schematic Capture and more.

In addition, our team excels in providing the design and engineering services and technical documentation necessary to quickly create a new product for your business.

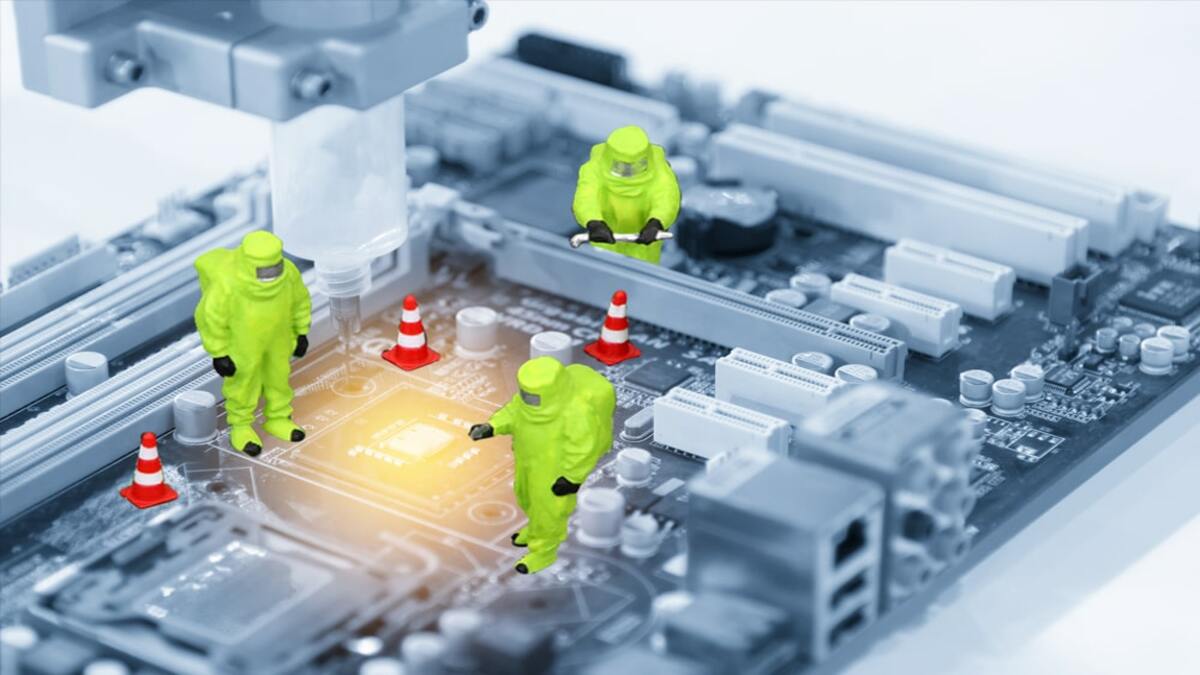

Testing

We conduct product sample testing and then start the production process in a mass unit. Our main goal is to avoid errors or defects in the early stage of agile manufacturing.

Our team of competent engineers and developers takes care of new product development after clearly defining technical specifications, deadlines, responsibilities and budget.

Product Manufacturing

This is the last stage when your hardware product goes through the production line. It is always better to test a sample of the first production batch. However, it is a cost-effective and well-thought-out decision to go with manufacturing outsourcing for high-quality work. Count on us and we will build a product prototype like never before!

When we are sure that the design is good, it is time to make factory samples. Making pre-production samples will give you an idea of whether or not the base product is attractive to users.

We then look for suppliers and manufacturers who make products similar to ours. This is not an easy task because you will find more representatives and fewer manufacturers.

Certifications And Patents

Consumer products often have compliance issues and complex regulatory issues. We have a strong network of patent attorneys for our product development clients and we sincerely strive to meet the requirements of RD Testing, FCC, EMC Testing and Safety Testing.

Our connections will help protect intellectual property and ensure high quality IP work at an affordable price. In addition, throughout the design process, we strive to meet specific CPSC product safety regulations in every way possible.

Commercialization

Here we will not bump up your production and help small businesses with the best unit costs without compromising on quality and delivery. This is possible because we have a team of engineers to ensure smooth production and a trusted network to partner with local and foreign manufacturers.

We are among the trusted companies providing product engineering services. We offer product design engineering services along with product manufacturing, so you don’t have to personally commit to the product manufacturing process.

So, are you ready to make your next product a huge success in the market? Call us now! We provide you with comprehensive product development services with robust creativity and advanced technology.

Final Words

It is quite evident that the right approach to the development and construction of digital products is rather a sophisticated adaptation that witnesses constant changes in processes due to changes in customer habits, tastes and behaviors.

However, disrupted supply chains will require more resources to procure materials that effectively accommodate the concept of customization and agile development.

Today, the pressure is more to minimize waste and maximize agility and productivity to evolve and grow with the functionality of technical product development worldwide.

We are a product engineering services company that provides holistic Embedded end-to-end product development services to enhance customer satisfaction and create new business models.

Our certified product development engineer and team of professionals will help you with the complete product development. So if you’re looking for hardware or product development expertise, Contact us now!